E1200C Series

The C series Winding Machine, specifically crafted for motor coils, comprises essential components such as a headstock with speed settings, faceplate, and a convenient foot pedal. The E-1200C Winding Machine adopts a floor-standing style for robust performance.

Versatile Options for Varied Coil Sizes

Our machines offer a diverse range of options, accommodating a maximum coil diameter of up to 1600mm and a powerful torque of up to 80kgm.

High-Powered Spindle for Efficient Operation

The main spindle is driven by a robust 5HP motor, capable of achieving a maximum shaft speed of up to 500RPM. Users can opt for a 20-60-120rpm selection to suit specific requirements.

Tailored for Motor Coils and Power Transformers

With these innovative features, our winding machines are adept at meeting the specific demands of motor coils and power transformers. This ensures high-performance and efficiency in the production processes of various coils.

Special Features for Enhanced Functionality

The standard model does not include a bench or guiding system. However, a separate traverse system, exclusively designed for use with the C series winding machine, is available. This system facilitates automatic wire guiding, further enhancing the functionality of the machine.

Machine General specification

| 200 Rpm versions | |

| Max Speed(Rpm) | Torque(Nm) |

| 190 | 158 |

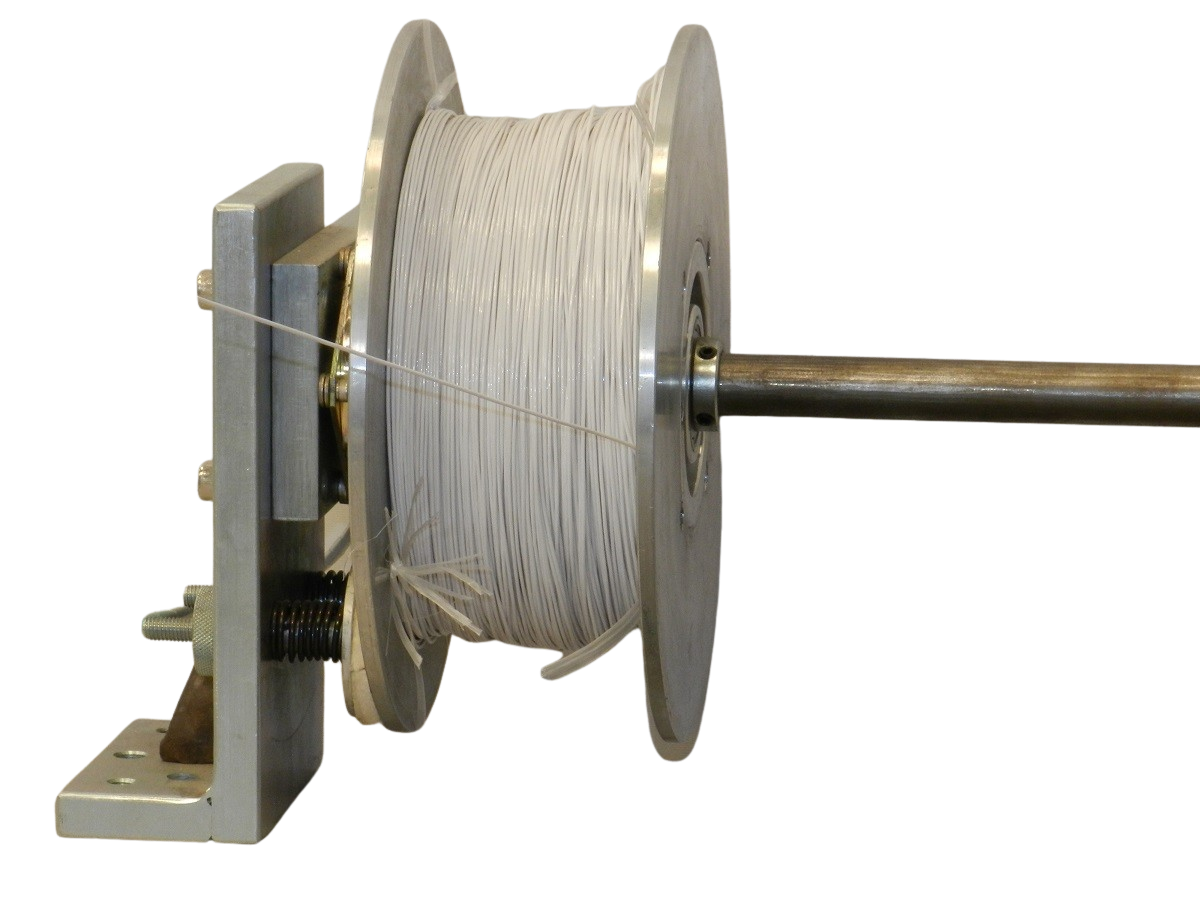

Guider Arm with GB-500 Guider

Mechanical Position Adjustment

Programmable wire guiding system with programmable pitch and coil width, This guide arm has facility for mechanical position adjustments, accommodating coil OD variations from 0 to the maximum. Its adjustable height and radius ensure optimal positioning for diverse winding requirements.

Integrated Wire Break Detector

Equipped with a wire break detector, the guide arm enhances operational reliability by promptly detecting any wire breakages during the winding process.

Efficient Assembly and Movement

The entire guide arm is assembled onto a ball screw carriageway with a generous 500mm winding length. This configuration ensures smooth and precise movement throughout the winding process.

Advanced Guider System

The guider system is comprised of a state-of-the-art brushless servo gear coupled with a high-efficiency ball screw. This combination, along with two precision linear bearings, delivers a linear and constant movement across the entire width of the guider. The advanced design guarantees precision and reliability in coil winding operations.

Products & Capabilities

E1200C

| Inch | mm | |

|---|---|---|

| Max no. Programable Winding | - | 10000(SD card) |

| Guider Motor (brushless) | - | Servo 1.2Nm |

| Max Winding Diameter | - | 800mm |

| Type of Programming | - | CNC Color Touch Screen |

| Electrical Supply | - | 220V+N+GND/50Hz |

| Guider Precision | - | 0.01mm |

| Net Weight | - | 1000Kg |

| Main Shaft Motor | - | Brushless Servo Motor |

| Max Winding Lenght | - | 500mm |

| Max no. Winding per Coil | - | 200 |

| Max Winding Shaft Speed | - | 190rpm |

| Face Plate Diameter | - | 350mm |

| User Interface | - | 7"color touch screen |

| Spindle Resolution | - | 0.01mm |

Guider Arm with GB-500 Guider

| Inch | mm | |

|---|---|---|

| Guider Programmable Width | - | 500mm |

| Guider Motor (Brushless) | - | 0.4 HP / 300 W |

| Guiding Precision | - | 0.01mm |

| Wire Brake Sensor | - | Included |

| Electrical Supply | - | 3 x 380Vca - 50Hz |

(1).png)

.png)

(1).png)

.png)

.png)

(1).png)

(1).png)

(1) (2) (1) (1) (1).png)

.png)

(1).png)