Tensioners

Wide variety of tensioner are offered depending on wire gauge, wire material and spool dimensions. These tensioners are offered along with suitable stand and spool enclosure.

Graduated Mechanical Tensioner(TCL series)

This precise tensioner unit is mounted on the stand and wire spool is to be kept vertically below the tensioner unit. The spool will be standstill and will not rotate. These tensioners comes in three options.

| Model | Tension Range(grams) | Suitable wire diameter (mm) | Suitable wire diameter (AWG) |

|---|---|---|---|

| TCL | 200-2000g | 0.20-0.60 | 22-33 |

| TCLL or TC2L | 1000-5000g | 0.50-1.20 | 16-24 |

| TC3L | 2000-10000g | 0.70-2.00 | 12-21 |

Magnetic Tensioner(NMT series)

Our magnetic tensioners utilize permanent magnets to regulate tension by adjusting the gap between the magnets and the main tension wheel. This non-contact tension mechanism ensures consistent tension over time, as it eliminates friction between mechanical components. These tensioners are available in three different options.

| Model | Tension Range(grams) | Suitable wire size(mm) | Suitable Wire size(AWG) |

|---|---|---|---|

| NMTC004-S120 | 4.0-120g | 0.03-0.14 | 34-48 |

| NMTC014-M400 | 14-400g | 0.06-0.25 | 30-42 |

| NMTC030-L800 | 30g-800g | 0.08-0.40 | 26-40 |

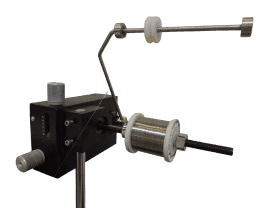

Standard Tensioner

This precision tensioner unit is expertly crafted for winding fine wire and is securely mounted on the stand, with the wire spool positioned vertically beneath it. Ideal for wire ranging from 25 gauge to 46 gauge, this tensioner unit is supplied as standard accessory for some of the winding machines and comes with stand and spool enclosure.

The standard spool base and spool enclosure have a capacity to accommodate spools with a maximum PT5 specification (top diameter: 148mm, bottom diameter: 158mm, and height: 175mm). For larger spools up to PT15 (top diameter: 180mm, bottom diameter: 300mm, and height: 227mm) with a suitable base, an alternative, more capacious spool container is available.

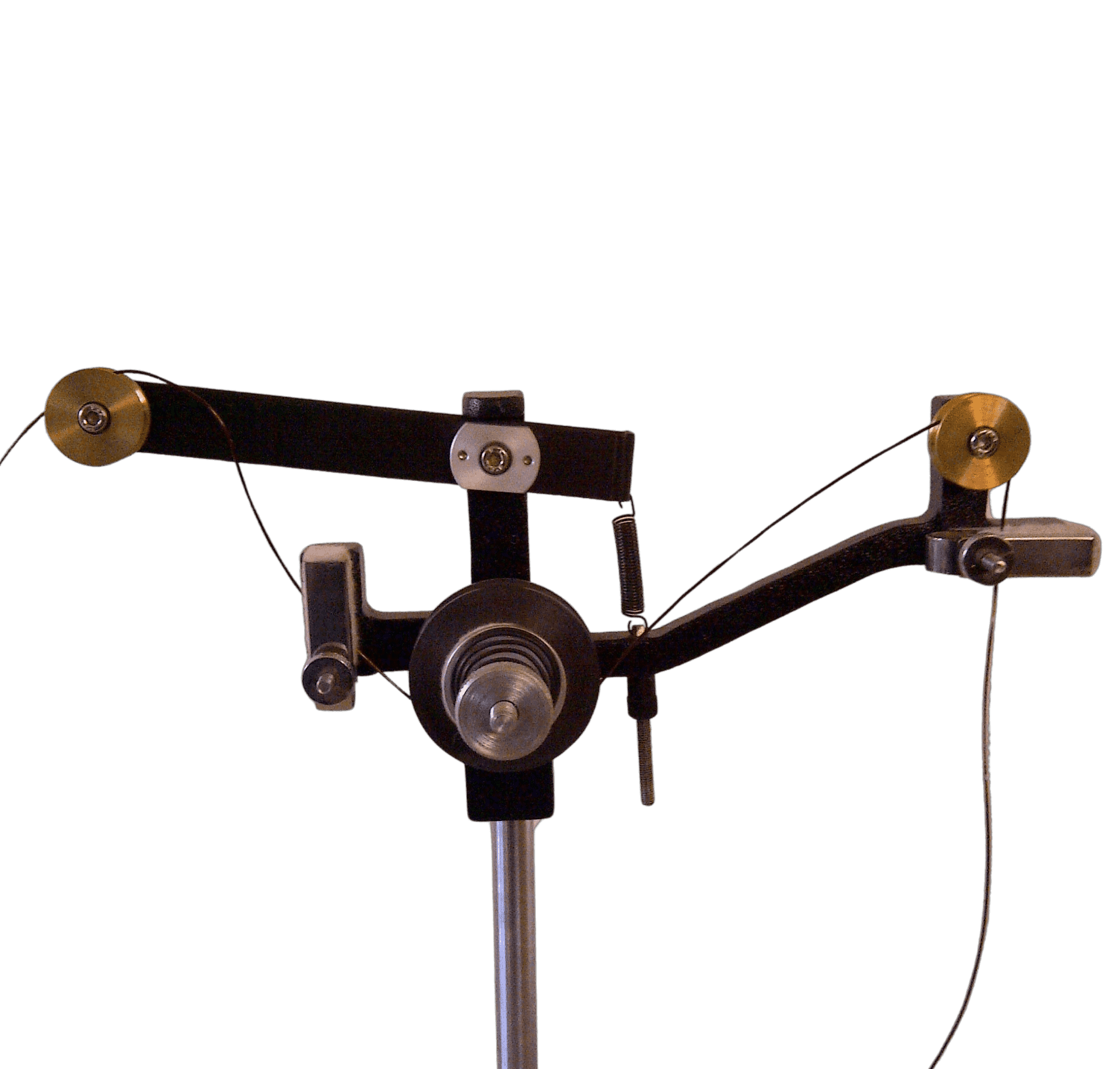

Horizontal Tensioner for Resistive Wire(GHTU)

These tensioner units are meticulously designed for winding resistive wires, preventing any twisting caused by wire hardness. The spool is horizontally mounted and rotates as the wire unwinds during the winding process. The standard tension range is from 80 to 250 grams. Additionally, the tension can be adjusted based on specific requirements by changing the springs.

Medium Tensioner (MTU)

Mechanically activated tensioner suitable from 30-15AWG wire helps to unwind easily for various sizes of spool.

Wire Bundle Dereeler

Some of the wires which come as a bundle and not in the spool required special payoff to make sure they are not caught in the bundle.

Electro Magnetic Controlled Tensioner(TH3)

Position this medium-sized floor-standing de-coiling tensioner conveniently in any factory or workspace. With a tapered barrel capacity, it caters to wires ranging from 0.40 to 3.00mm, making it versatile for various applications. The inclusion of an electronic braking system ensures precision during operations.

The electrically powered braking system governs the main pulley of the brake, offering highly repeatable settings. Adjustment is seamless, facilitated by a digital potentiometer or can be integrated into the main winding machine software. This user-friendly and reliable control mechanism enhances operational efficiency.

Technical Data:

Wire Diameter : from 0.40mm to 3.00mm

Max. Tension : 18kg

Max. torque : 12Nm

Max. Rotational speed : 40rpm

Max. Power consumption : 25W

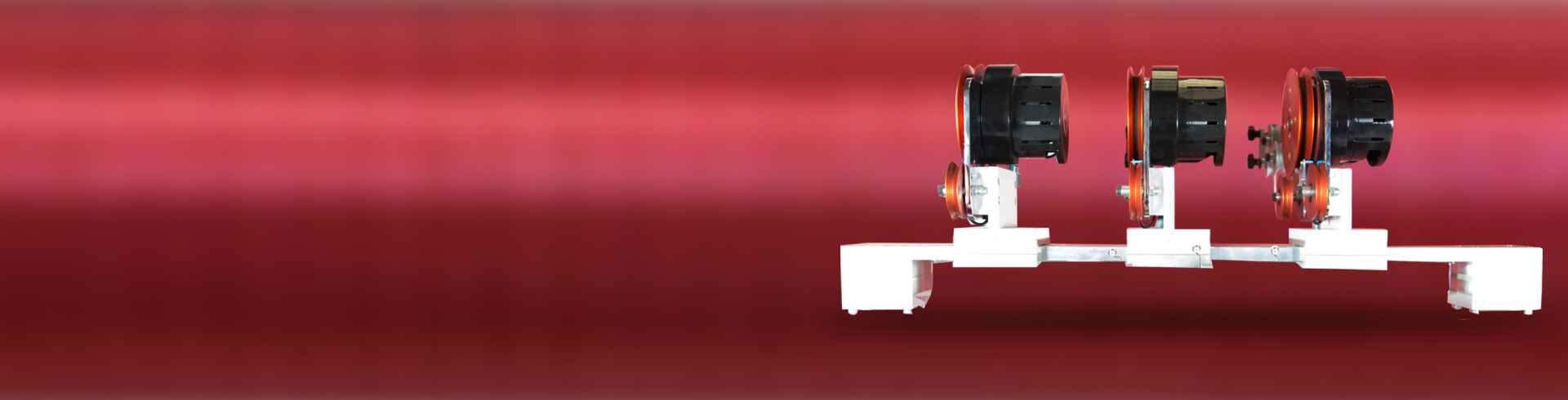

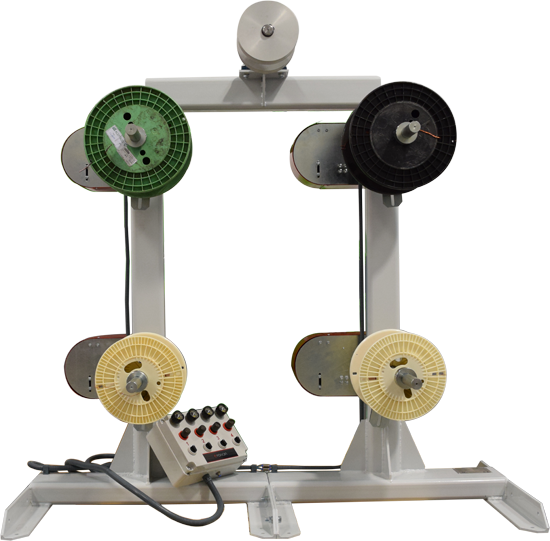

Electro Magnetic Control Tensioner Cum Spool Holders (DP series)

This medium-sized floor-standing de-coiling accessory is easily positioned for convenience. The profile wire de-coiling device is available in single, two, and four spool capacities, featuring a hydraulic disc braking system controlled by a pneumatic actuator.

All controls are conveniently placed at the front of the machine, accompanied by pneumatic gauge indicators displaying tension levels. Additionally, a brake tension release switch is provided for manually moving the wire at the beginning of the winding process.

DP - 1

Electro-magnetic control tensioner cum spool holder for single spool.

DP - 2

Electro-magnetic control tensioner cum spool holder for two spools.

DP - 4

Electro-magnetic control tensioner cum spool holder for four spools.

Technical Data:

Max Weight per coil : 250 Kg

Max spool flange : 750 mm

Max width (height) spool : 460 mm

Standard spool shaft diameter : 36 mm

Max No Spools : 1 or 2 or 4 pcs

Air Supply (low volume usage) : 6 Bars

Single Spool Holder Cum Tensioner(Mechanical)

Single tensioner cum spool holder will hold the wire spool horizontally and rotates complete spool while de-reeling wire or strip and the tension will be adjusted through tension knob. Single Tensioner cum spool holder can hold spool weighing upto 50Kg/100lbs with diameter of the spool upto 700mm and width/height upto 500mm. Single tensioner cum spool holder is recommended for wire from 0 gauge to 15 gauge or for strips. Some sort of spool lifting equipment is required as the shaft is fixed on the pillar.

Heavy Payoff

Heavy Payoff holds the wire spool horizontally and rotates complete spool while de-reeling wire and the tension will be adjusted through tension knob. Heavy payoff can hold spool weighing upto 25Kgs/50lbs with diameter of the spool upto 300mm and width/height upto 250mm. Heavy payoff is recommended for wire from 8 gauge to 25 gauge.

Servo Tensioner(BTSR)

This servo based tensioner are controlled through servo motor and can be programmed as stand alone or through winding machine.