Coil Winding Machine

The coil winding machine is critical in coil manufacturing, influencing quality, quantity, and winding patterns. While some may assume any machine capable of rotating a bobbin or former is suitable, this assumption is incorrect. Selecting the right coil winding machine is paramount for optimal coil winding processes. In this article, we explore one essential requirement—Non-Orthocyclic Winding—and later delve into other crucial factors in electrical coil manufacturing.

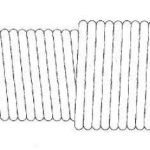

Non-Orthocyclic Winding:

Non-Orthocyclic winding refers to a specific pattern where each layer of wire on a bobbin is wound in a manner that introduces a skew or criss-cross effect. This method ensures that each subsequent layer is wound in the opposite direction to the previous layer, resulting in turns that are not parallel to each other. This technique effectively utilizes 75-80% of the available space within the coil. However, it inherently leaves air gaps between turns, which can lead to increased coil temperatures due to trapped air heating. Although varnishing the coil can mitigate this issue, it does not entirely eliminate the additional space required for winding the specified number of turns.

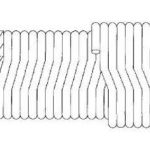

Orthocyclic Winding:

Orthocyclic winding, in contrast, is characterized by a parallel winding pattern. Each turn is wound sequentially in its designated location, minimizing the air gaps between turns. This continuous winding process ensures that turns are predominantly parallel to each other, except for the fraction of each turn where the wire shifts to the next position. Consequently, orthocyclic winding achieves a higher copper density within the given space of the bobbin, utilizing approximately 90-92% of the available area. This denser packing of copper reduces air gaps significantly, thereby enhancing coil performance by minimizing heat buildup.

Benefits of Orthocyclic Winding:

Orthocyclic winding offers several advantages:

-

Higher Copper Density:

Accommodates more turns within the same winding space.

-

Reduced Air Gaps:

Minimizes heat generation, enhancing coil efficiency and lifespan.

Conclusion:

Acme Mechatronics, Inc. exclusively supplies coil winding machines equipped with orthocyclic winding patterns to optimize copper density and reduce air gaps. This approach ensures superior quality and performance in all electrical coil applications.

For a visual demonstration of orthocyclic winding, watch our video tutorial here.

By prioritizing orthocyclic winding, manufacturers can achieve coils that not only meet but exceed industry standards for reliability and efficiency.